2023-03-06 Spinning fusion is the most widely used one-step spinning forming process for forming non-woven fabrics. The spunbonded nonwovens are formed by continuous filament fibers, the production line speed is high, the product strength is high, and the dimensional stability is good, but the bulkiness is low, and the uniformity of web formation and surface coverage are slightly poor.

Read More

2023-02-28 Under the requirements of the "Plastic Restriction Order", non-degradable disposable plastic bags have gradually withdrawn from the market, and reusable non-woven bags have become one of their main substitutes, and are widely used in supermarkets, catering, takeaway and other fields.

Read More

2023-02-27 Isotactic polypropylene fiber has excellent characteristics such as rich raw materials, high strength, light weight, good chemical resistance, insect and mold resistance, and less staining and pollution. The fibers in polypropylene melt-blown cloth are arranged irregularly and disorderly.

Read More

2023-02-22 In the case of continuous prevention and control of the new crown epidemic, many places have resumed work and production. Among them, masks are still a necessity and are still in short supply.

Read More

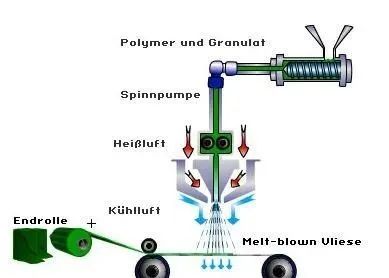

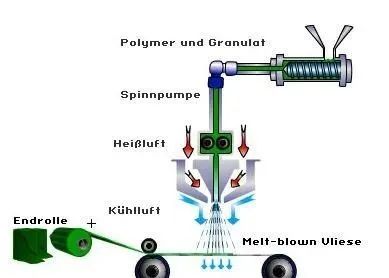

2023-02-22 Melt-blown cloth is to use high-speed hot air flow to draw the thin stream of polymer melt extruded from the spinneret hole of the die head, thus forming ultra-fine fibers and collecting them on the condensation net curtain or roller, and at the same time bonding themselves to become Melt blown nonwovens. The width of meltblown cloth from regular manufacturers is generally 1600mm, 2400mm, and 3200mm, and the diameter of the extruder is usually 90mm, 105mm, and 135mm.

Read More

2022-10-17 Due to the worldwide coronavirus (COVID-19), there has been a huge shortage of N95 masks, surgical and medical masks, etc.Most of the masks need to use spun-bond fabric and melt-blown fabric. Seek winwin company has more than 19 years of experience in the non-woven field. Melt-blown machine and spun

Read More